COB LED Lights

Picking an LED innovation resembles picking the right winter coat to wear; there are diverse models that give offer a variety of elements depending upon what you may require. When you choose the elements, you need from your LED, you can without much of a stretch pick the package type accordingly. The “package type” refers to the way an LED’s semiconductor die (similar to the fiber in an incandescent) is packaged inside LED gadgets for various applications.

The LED bundle can be extremely application-specific, as with the DIP LEDs, or it can be exceptionally flexible to handle bunches of various needs, for example, with the SMD bundle. Cutting edge LED innovation was first introduced in 1962 by Nick Holonyak with his development of the DIP LED. The LED business has been enhancing the said technology since then. There are various types of LED package technology used in market today.

What is Chip on Board (COB)?

The latest LED improvement has been “Chip On Board” or COB innovation. COB and SMD can be comparative. Since like SMD, COB chips have different diodes on the same “wafer” or chip, this is the place where the similarities end between these two. Hence, on each COB chip there are various diodes; regularly 9 or more.

The other huge difference amongst COB and SMD innovation lies in the way that while SMD requires a circuit for each diode included on the chip, COB applications just have 1 circuit and 2 contacts for the whole chip deals very small to the quantity of diodes. This single circuit configuration, paying little respect to the quantity of diodes on the chip, produces ease for COB LED applications. However, COB lights produces higher lumen-per-watt proportions in contrast with other LED advancements, for example, DIP and SMD. Unfortunately, the huge drawback from the single circuit configuration of COB chips is that different channels are important to alter singular levels of light yield to make color changing impacts. What this fundamentally means is that COB innovation, while effective and productive in single-shading applications, can’t be suitable for color changing lights.

Before COB innovation, LED spot lights and flood lights were verifiably considered “non-standard lights” since they required different LED sources to create a high lumen yield. Since the approach of COB chips in the LED enclosure, a huge lumen calculation can be delivered from a single source utilizing a COB chip.

Other than spot lights and floodlights, COB chips have been put into a wide range of lamps and utilized for various different applications also. Indeed, COB innovation is utilized for small devices with high intensity, for example, a Smartphone or camera. The standard is that COB chips creates a lot of lumens but no energy, which is vital for any gadget that keeps operating on a battery. Numerous Smartphones have a little 2×2 or 3×3 COB network to deliver their camera streak. Simple to use cameras also strengthen a small COB chip that will utilize small energy, power and produce a lot of light.

COB chips vary broadly in their applications and along these lines diverse chips will require different wattage, voltage, and will deliver tremendously diverse lumen calculations. Though COB chips produces high proportion of lumen per watt, normally provides 80 lumens for each watt and 100 lumen for every watt.

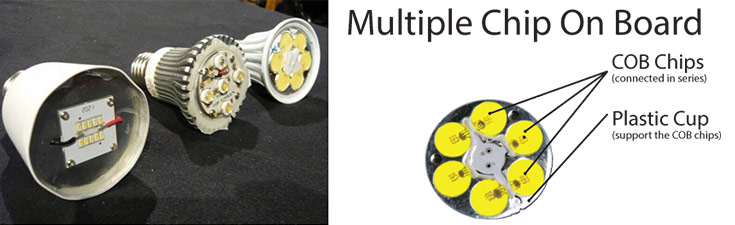

What is Multiple Chip on Board (MCOB)?

Since the making of COB chips, a variation has labelled along called MCOB or “Multiple Chip On Board”. MCOB gadgets are fundamentally the same as COB chips in their application and are pretty much similar to COB chips connected together in an arrangement. MCOB devices are different from COB since they are better for low wattage applications. They additionally don’t satisfy the standard light requirements for spot light and floodlights, as described above in the

COB segment. While MCOB gadgets don’t meet the conditions to end up a standard light, they deliver a significant amount of light and are extraordinary for low wattage conditions like A19 lamps. However, A19 lamps are as of now the most widely recognized utilization of MCOB innovation. If you purchase a LED A19 lamp sooner rather than later, it will probably be a MCOB lamp.

MCOB is another innovation that very few makers are delivering. There are numerous applications for a high lumen calculation that MCOB can satisfy, and possibly trend-setters will utilize the innovation to make new items that the business sector has never seen. The universe of LED lighting is energizing when we see that it is changing and developing just before our eyes. Before long we may have yet another innovation that is a competitor in the LED market!

What is Dual In-line Package (DIP)?

Double In-Line Package LED innovation has been around for over 50 years, and is likely what you imagine when you picture a LED. Despite the fact that it is old, DIP LEDs are a long way from obsolete as they are still utilized broadly in various applications.

The boundless utilization of DIP LEDs came to fruition because of their long life-range and extreme splendor. Plunge LEDs are profoundly visible by their “pill” or “shot” molded outline (≤5mm wide), and the long contacts that protrude from the base of the LED which can be effortlessly bound or embedded into a bread board. The LED’s plastic and epoxy packaging really serves as a lens that can center the light originating from the diode. The state of the external packaging additionally incorporates a level edge on one side that dependably indicates the cathode side of DIP LEDs.

These lights, when utilized for private or home use, are normally found in hardware as pointer lights as a result of their minimal effort, high shine, and simplicity to introduce. DIP Diodes can be purchased in mass by hardware producers to satisfy numerous reasons; and as a result of their plug-and-play nature, can be effortlessly patched to any sort of circuit board. This gives electronic gadgets the capacity to send data to the client without the requirement for a genuine presentation on the gadget.

These LEDs will normally deliver somewhere around 3 and 4 lumens for every LED. They regularly keep operating at between 5v to 24v, with 12v being the most well-known voltage. They separately pull somewhere around 0.05 and 0.08 watts. This creates somewhere around 35 and 80 lumens for each watt, contingent upon the genuine LED.

What is Surface Mounted Diode (SMD)?

The SMD chips, or “Surface Mounted Device” chips, have turned out to be extremely well known because of their flexibility. SMD LEDs have been utilized to make everything from lights to strip lights, and even missed call pointers on mobile phones. These chips are much littler in contrast with the DIP innovation, which tends to give them the additional adaptability over DIP diodes.

SMD innovation support chips with more convoluted plans, for example, SMD 5050 chips (portrayed to one side), that have RGB capacities on a solitary chip. It is comparatively more intense for mixing shades, rather than the DIP innovation, which can just show one hue or shade for every gadget. The innovation does not take the slug formed outline from DIP LEDs, and is nearer to that of a level, square PC chip. It is likewise important that SMD chips can have more than two points of contact (one anode and one cathode). SMD chips can have 2, 4 or 6 contacts, depending upon the quantity of diodes on the chip. With the SMD outline, there is an individual circuit for every diode. For instance, SMD 5050 chips have 3 diodes on the chip, which means 3 circuits and a sum of 6 contacts.

SMD chips have been an essential improvement for the LED business in terms of the capacity, for example, it can put 3 diodes on the same chip. A single chip which incorporates a red, green, and blue diode, results in a piece of hardware that can produce any color you need by altering the level of yield from every individual diode on the chip. Since they are compact and more versatile, these chips are utilized widely for LED strip lights and lights. SMD LED chips are available in many sizes, the most well-known of which are SMD 3528 and SMD 5050S. SMD 3528 chips are just 3.5mm wide, and SMD 5050 chips are 5 mm wide. SMD LEDs can be made much smaller than the 3528 and 5050 chips. Some of these chips are made small enough to go in top of the line hardware, for example, mobile phones and smart phones marker lights.

SMD chips that we find in lights and strip lights will ordinarily produce between 4 to 5 lumens for every diode on a chip, (for example, a 3528, single diode chip). These chips will normally keep operating at either 12v or 24v, with 12v being the most well-known. Exclusively these chips can pull between 0.05w to 0.08w (single diode, 3528) up to between 0.15w to .24w (three diode, 5050). This implies that these chips can deliver somewhere around 50 and 100 lumens for each watt depending upon the specific chip.

Structure of COB LED

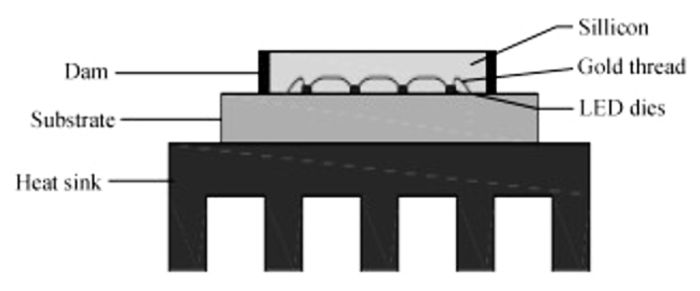

Anatomy of COB lights

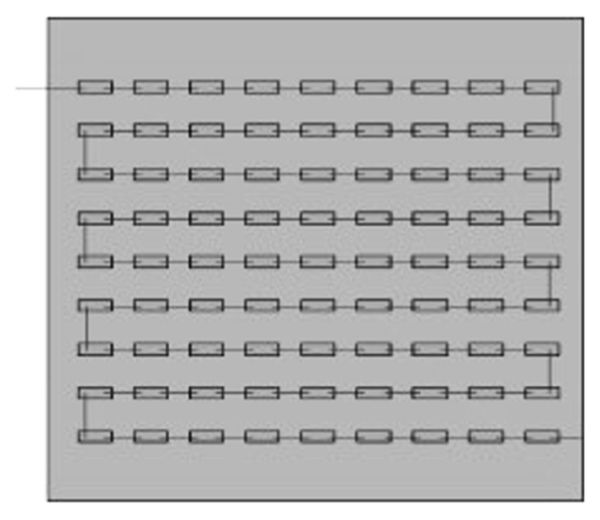

The essential COB design is appeared in figure. LED dies are put on the substrate in the die-bonding process. Gold wires connect these LED dies in arrangement parallel after wire-holding. Silicon is utilized to show outside ecological impact and unblocking the light exit. The substrate attempts heat dispersal, electrical association and light reflection. In application, the COB light source is specifically laid on the heat sink of the light without the center PCB circuit board layer.

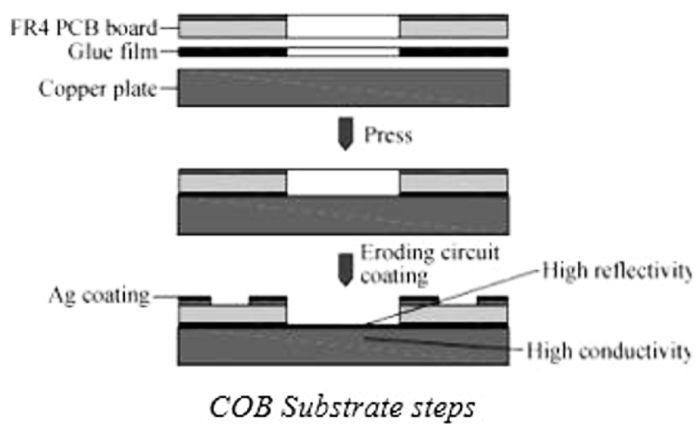

For the most part, COB setup plans ought to take two qualities into thought: high temperature conductivity and high reflectivity. Here, copper plates are utilized for COB substrates because of their magnificent heat conductivity, and slim FR4 PCB sheets subsequent to opening a window are received for electrical steering and association in view of their great electrical plans. Electrical protecting glue film are placed between the copper layer and FR4 PCB board.

Finally, the Ag covering is saved on top of the copper for high light reflectivity, which offers more light extraction.

Different phases of COB substrate manufactures as shown in figure below.

COB bundling LED sources in lighting application are routinely controlled by direct current with DC–DC converters on the other hand AC–DC converters. In this way, COB lighting arrangements incorporate both COB packaging structure and COB driving plans. The two frameworks are generally accomplished freely. The reconciliation of packaging and controlling would be worthwhile for lessened cost, and improved manufacture and upgraded quality prompting a superior answer for LED lighting application.

Circuit & Electrical Arrangement inside COB LED

Electrically, high voltage LED modules have turn-on voltages that are nearer to the main supply than customary high current LEDs, which are low voltage gadgets. High voltage LEDs can be portrayed either utilizing little quantities of high voltage LED dies or vast quantities of low/medium LED dies. With quick advancement of LED semiconductor innovation furthermore, a dropping cost of LED dies, low/medium LED turn out to be increasingly appealing on expense. Thus, Low power LED dies are associated in arrangement to shape high voltage load as illustrated in figure.

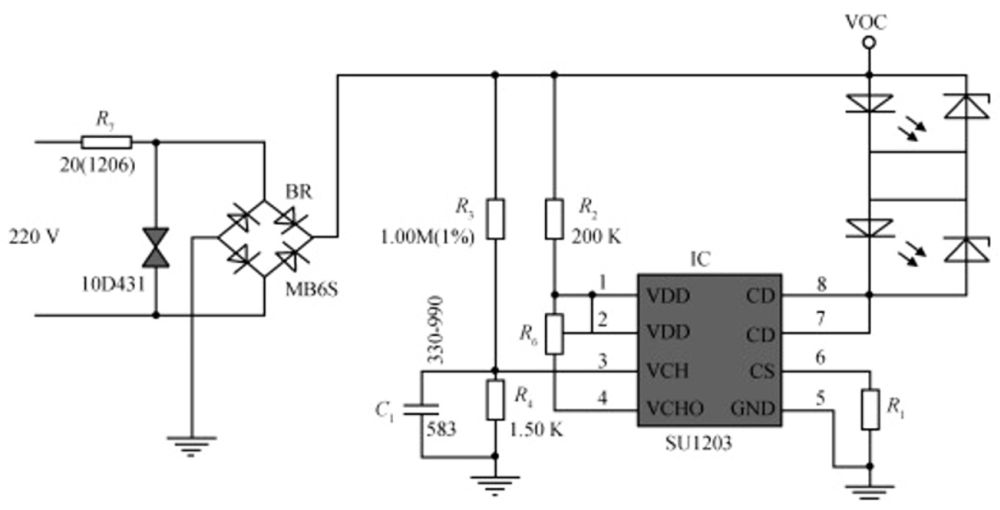

AC–DC converters are normally costly, irresistible, and are hard to coordinate onto the COB substrates. A unique beat drive IC gadget fueling technique is presented in the designing. The IC gadget gives less segments and no requirement for an electrolytic capacitor; a minimal effort, high productivity and high quality can be accomplished. The IC controlling LEDs as shown in figure:

▲ AC Direct Driving LED

The IC circuit can be coordinated on the highest point of the FR4 PCB board. LED chip is associated with the bridge anode and the other end of LED chip is connected with the containers of IC. At the point when AC supply power is associated, the extension is masterminded to accomplish the high voltage full-wave correction. The current through serial LEDs is drive by the IC. This reconciliation of the bundling and controlling technique gives minimal effort, high productivity and higher reliability for high power COB lighting.

Performance Characteristics of COB Lights

There are different reasons why architects will need to genuinely consider COB LEDs for their next outline. In a late report offered by Research and Markets, investigators take note of that COB LEDs, which are wide-range light emitters (so they additionally can be utilized as a part of thruway and streetlights), convey three important advantages: better color combination, better lighting impact, and low heat resistance necessities. However, on the grounds that these COB LEDs give high power thickness, more proficient heat distribution, and require a small amount of the board space, they are exceptionally reasonable for many general lighting applications, as indicated by the company’s examiners. Some of characteristics of COB lights are:

Thermal characteristics

In COB package, the particular area for measuring temperature (Ts) is not designated. Because LC0XXB arrangement are made of metal substrate, which has the high heat conductance. In this manner, there is no compelling reason to outline an extra Ts point for holding thermo-couple link. At the point when Ts should have been measured, one of both cushions can be Ts point. In addition, it is anything but difficult to bond the thermocouple link in vast area. If the users don’t have the clear idea about the right Ts estimations strategy, a major mix-up might be made in the calculation procedure. In this manner, it can’t be underlined enough that the calculation technique must be checked in each testing forms.

As appeared in figure below (a), the Ts purpose of COB are portrayed in dotted circle line. In figure (b), the little square is not for the calculation but rather for the fiducial characteristic of creation procedure. At the point when holding the thermocouple onto anode, the excess holding paste might be required in order to bond the thermo-couple link. However, this abundance holding glue ought to be the reason for the mistake esteem in estimations.

Electrical characteristics

LED lights is determined by steady current and the most package creators regularly supply LEDs binned by consistent current. In the fundamental LED applications, the steady flow driver is similarly prescribed to be utilized for work. So we give the information, which can be useful to outline lighting. Though, it is only for reference. COB can be described like as LED module items. Since the optical, electrical and temperature practices are near the LED module which have a great deal of lighting source.

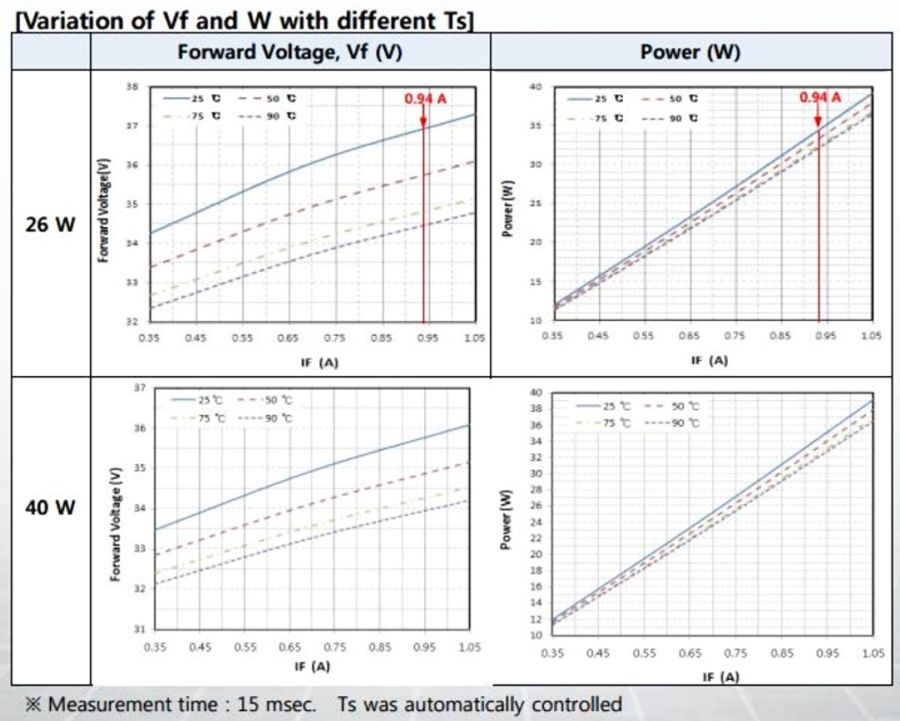

In this area, the optical properties are portrayed with different operation streams and raised temperature, which is near genuine frameworks. Ts was naturally controlled at 25, 50, 75 and 90 ℃. The electrical properties of LC026B and LC040B are appeared in beneath figures. The forward voltage of COB is the combined properties of the serial associated chips. As Ts slopes up the forward voltage (Vf) step by step reduce. At the same Ts, the force and Vf increases with operation currents (If). Furthermore, for safe planning luminaire, the operation current must be similarly chosen inside most extreme rating conditions.

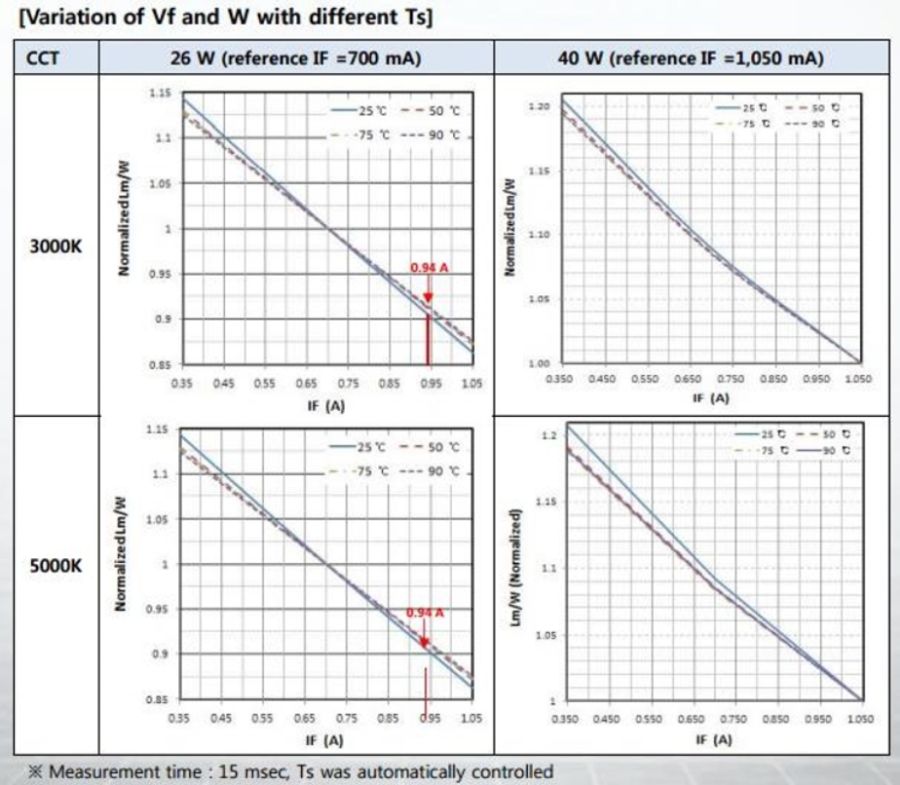

Luminous characteristics

COB demonstrates the steady decrease of a glowing adequacy with an expansion of operation current. It is exceptionally broad phenomena in ordinary LED. However, glowing flux is different with Ts the slope is exceptionally comparable to inclination at same Ts. The different conduct of 25 ℃ may come about because of the variety of Ts by the expansion of operation current of COB, which ought to influence to electrical properties.

At the point when the powerful LED are estimated the warm impact by current as a rule make it to calculate the attributes of LED. In spite of the fact that these beneath information are useful to plan, in genuine set, analyst ought to consider the variety of properties in an air conditions being used.

Color characteristics

COB is furnished with the shading consistency of MacAdam 3 stage. Though, many mistakes are made in outlining lighting process. The light color is variable through second optic way, for example, diffusing plate, lens or reflector.

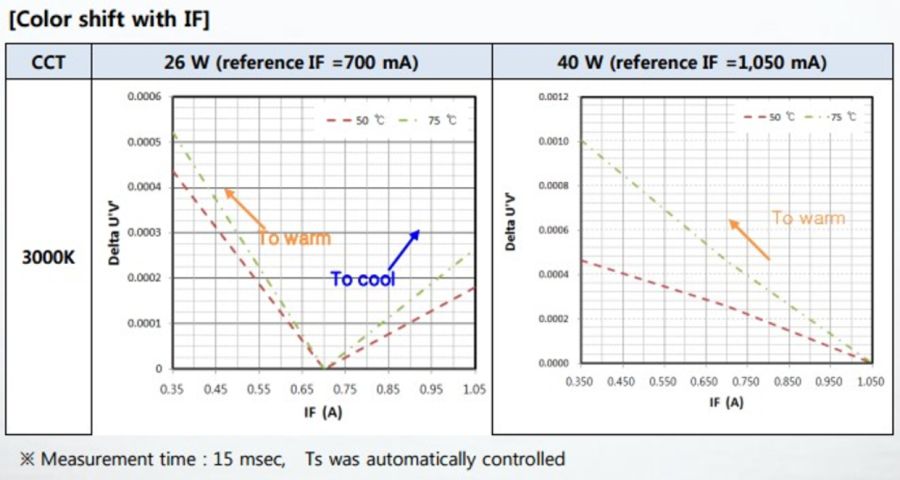

The beneath figures demonstrate the shading change of LC026B and LC040B with expanding operation current. The color movement is portrayed as delta U’V’ and the reference current are given with COB power separately. Despite the fact that there are little shading shift in figure, in genuine lighting framework, it will be sufficient to realize aggregate color shift by different variables (temperature, operation current, fixed lighting framework and so on.).

Above all else, before choice of second optic segments, (for example, diffuser, and reflector) the client need to consider the shading shift by included optic parts.

Specification of COB LED

COB lights used in many applications, thus these lights have its own specifications and functions that is being used in different forms. The important factors to be considered is power efficiency, operating voltage, consumption of LED and so on.

Specification of COB lights

Comparison of COB lights with different manufacturers

There are many manufacturers that designed same type of product. However the specifications and requirement of each product is different. Below are the specification and performance comparisons of some of the biggest competitors with COB lights.

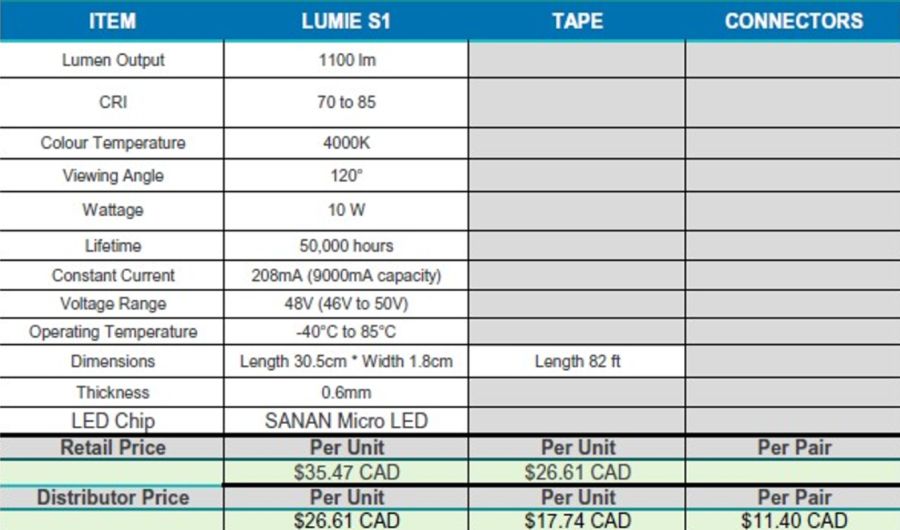

a) COB lights vs Philip series

i) The luminous flux of COB lights is higher. They produces 1100lm lumen output whereas Philip series COB LED downlight produces 800lm luminous flux.

ii) Color temperature of this COB light is fixed i-e 4000K, while Philip series offers different color temperature depend on the color of the light.

iii) Cob lights operated at 48V while Philip series COB lights operated at 220V.

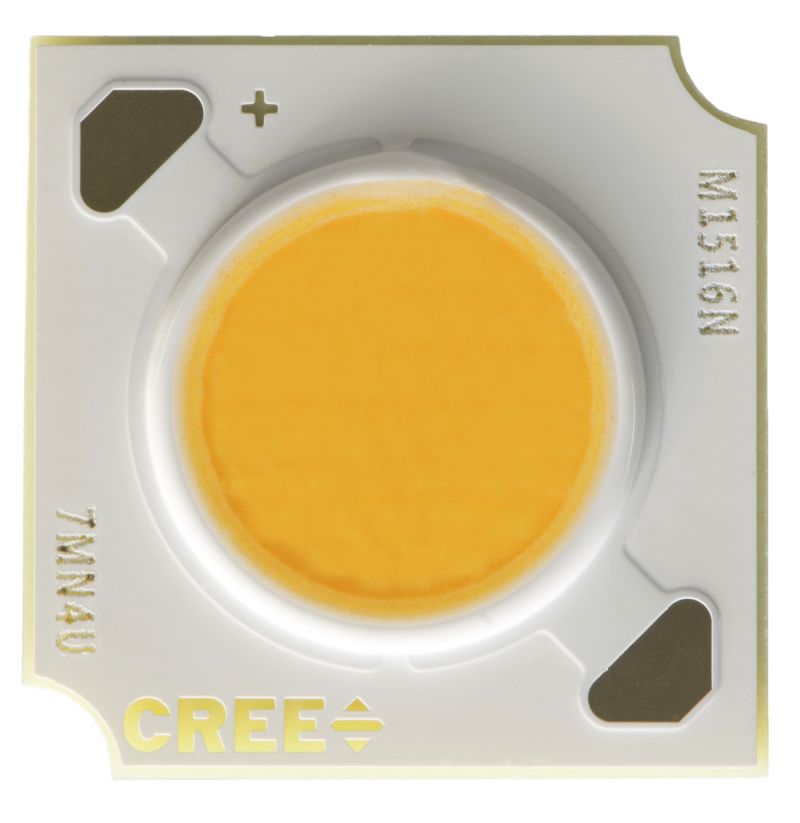

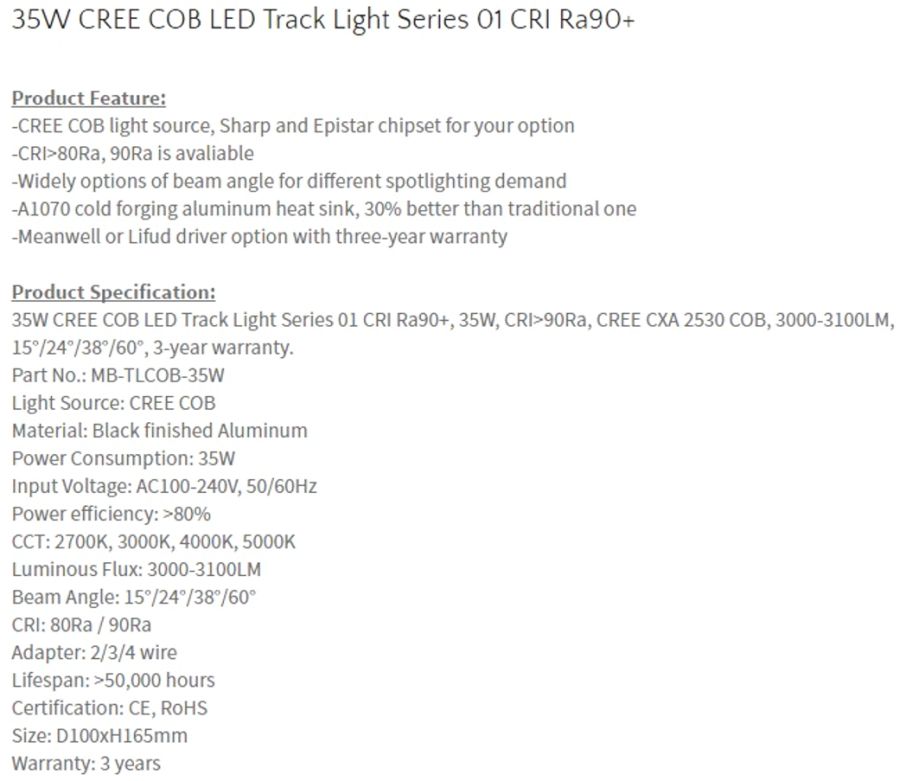

b) COB lights vs Cree series

i) CRI of COB light lie between 75-80. Cree series provide higher CRI >80 Ra or 90Ra.

ii) CCT of these light is constant i-e 4000K whereas Cree series COB LED offers different color temperature.

iii) Life span of both series is somewhat similar. COB lights and Cree series both works continuously up till 50,000 hours.

iv) Beam or viewing angle of these COB lights are higher i.e. 120°, whereas Cree series beam angle varies i.e. 15/24/38/60°.

Statistical and Case Study of COB Lights

The COB LED Market is depend upon to achieve USD 9,179.7 million by 2020, as per another study by Grand View Research, Inc. Expanding urbanization and base spending are depending upon to be the key drivers for business sector development over the estimation time frame. COB LEDs are power effective, have higher dependability and require less space. Moreover, they offer high power and homogenous light, which makes them appropriate for high power applications. As of late, the utilization of strong lighting innovation as against conventional lighting has essentially prompted expanded selection of COB LED.

Popularity for COB LED inferable from expanded selection by a few lighting application sections to pick up advantage over advances, for example, CFL and radiant lighting is similarly anticipated that would decidedly affect the worldwide business sector throughout the following six years. Moreover, progressions in configuration and cost saving through economies of scale are required to give higher development chance to the business sector over the measured time frame. Though, the complicated fabricating procedure and high cost combined with fluctuating worldwide financial conditions might be a test for industry members.

Further key discoveries from the study propose

- The light section overwhelmed the business sector and is required to be the biggest and quickest developing application throughout the following six years. This section represented more than 45% of the business sector in 2013, predominantly as a result of COB LEDs’ wide area light radiating property. Backdrop illumination application portion is dependent upon to become significant because of the increase in the quantity of utilizations in handheld gadgets, screens and LED TVs.

- Asia Pacific represented more than half of the worldwide business sector income in 2013, and is required to overcome request over the estimated time frame. Further, it is dependent upon to show the speediest development from 2014 to 2020, attributable to government activities favoring COB LED reception and huge number of business sector members.

- Organizations working in the business sector incorporate Philips LumiLEDs Lighting Company, Cree Inc.,Samsung Electronics Co. Ltd., Citizen Electronics Co. Ltd., Osram Opto Semiconductors GmbH, Everlight Electronics Co. Ltd., Seoul Semiconductor Co. Ltd., Nichia Corporation, Lumens Co. Ltd, LG Innotek Co. Ltd, and so on. The business sector is united in nature, and advancement of proficient and financially savvy items is relied upon to serve as a key development procedure over the estimate time frame.

The income for the worldwide COB LED Market is depend upon to reach to $3.5 billion in 2016 at a CAGR of 38.5%. APAC will remain a pioneer in general COB LED market. With the end goal of this study, Grand View Research has fragmented the worldwide Chip on Board (COB) Light Emitting Diode (LED) market on the premise of use and area:

- COB LED Application Outlook (Revenue, USD Million, 2012 – 2020)

Automotive

Backlighting

Illumination - COB LED Regional Outlook (Revenue, USD Million, 2012 – 2020)

North America

Europe

Asia Pacific

RoW

Advantages of COB LED

With the quick extending of the solid state lighting (SSL) innovation, the COB (chip-on-board) increasingly got to be in core interest. Reason for the better qualities, for example, low heat resistance, low glare file, uniform luminance and so on. It is comprehended that the utilization of COB Packaging innovation in the presentation, with the customary packaging innovation cannot coordinate the important points. The document expects to clarify the benefit of the COB bundling contrasted and the conventional LED bundling on five parts:

Manufacturing Effectiveness

The generation procedure of the COB is same as the conventional SMD, for example, the strong precious stone, wire. In any case, for the profitability of liquid controlling, color detachment and bundle, the COB is much higher than the SMD. The expense of the work and the material of the SMD is around 15% in the aggregate, in the other hand, it is only 10% for the COB, which implies if you utilize COB in your LED lights, 5% of the expense can be spared.

Super Thin

As per the real needs of clients, the thickness of the 0.4-1.2mm thickness from the PCB board, so that the weight is lessened to at least 1/3, the first item can be altogether decrease the structure, transportation and building costs.

Low Heat Resistance

The best approach to disperse heat of the SMD is Chips – strong paste – bind – patch glue – copper foil – protecting layer – aluminum plate, the one for the COB is shorter, just Chips – strong paste – aluminum plate. That is the reason the heat resistance of the COB framework is lower than the SMD, and that produces the more helpful life for the LED lighting.

Quality of Light

The bundling of COB is coordinated style, it is range light source, the point of interest is enormous visual edge and simple to change it, furthermore to cut the loss of the refraction of light, however the SMD is bundled by a few discrete units to stick in PCB plate. COB packaging utilized shallow circular light; the visual edge is more prominent than 175 degrees, near 180 degrees, and has more magnificent optical diffuse shading sloppy light impact.

Strong radiation capability

COB items is the light bundle on PCB board, the PCB copper foil rapidly spread the heat wick, and PCB copper foil thickness have strict specialized necessities, combined with overwhelming gold procedure, barely creating genuine light lessening. So couple of dead lights, incredibly developing the life of the LED.

Can be bent

The capacity to twist COB bundling is unique qualities, PCB won’t make harm the LED chip, so the utilization of COB module can be effectively delivered LED bended screen, circular screen, and wavy screen. Can be consistent joining, the creation structure is straightforward, and the cost is far lower than the adaptable circuit board and the customary presentation module LED generation.

Applications of COB LED Lighting

In application, COB LED module makes generation of lighting maker more basic and helpful, and reduces cost. In progress, the current innovation can help high return and huge scale COB module producing. With the improvement of LED lighting market, lighting interest is becoming quickly, as indicated by various lighting applications, we can deliver an arrangement COB light source module for large scale manufacturing.

COB LED Grow Light

New innovation is by all accounts quickly creating in the LED grow light industry, particularly inside the most recent couple of years. Galaxy-hydro just discharged their new arrangement of COB LED grow lights, accessible in either 200w, 400w, 800w, 1200w, 1600w adaptations. Utilizing COB (chip on board) innovation, these lights accomplish the best light extent by utilizing the most enhanced color consistency, energy and light efficient.

The Galaxy-hydro COB LED Grow Light gives the indoor producer a high ground on appropriate photosynthesis. It appears to perform well with all phases of development since it utilizes many components to incredibly enhance the general effectiveness of the light. Utilizing the most recent COB innovation with a perfect range, it can deal with any size of indoor horticulture enclosure on account of it’s fabulous daisy chain include that keeps your area organized, as well as empowers extra scope in any region that isn’t getting proper lighting.

With a 2 year guarantee and a 50,000 to 100,000 hour lifespan, it’s great to suggest for any individual who needs a compelling grow light that wouldn’t like to burn up all available resources.

Spotlight / downlight

COB lights can also be used as spotlights/ downlights. COB downlights is made up of aluminum with 6063 high quality air aluminum and Minimal effort spread you can discover thickness <2mm or less. It produces high brightness which varying in cost.

Ceiling Lights

Ultra violet COB roof light is composed of COB emitters and coordinated with warm, electrical, mechanical and optical persective. The configuration is to streamline the structure with a little measure of segments to accomplish the objective. Other than with the superb lightning arrangement frameworks, the item gives a broadly utilization of space from private to business applications, for example, retail locations, business spaces, hotels, general store, restaurants and outlets.

Conclusion

In the lighting of COB LEDs, high reflectivity and, high conductivity are both vital parts in structure of LED lights. COB lights provide many additional features; it incorporates multiple LEDs in a single chip which offers high luminous efficacy, high power factor, high color rendering index and works properly at 40°C to 85°C temperature. It uses in many applications such as; tracking lights, retails, clothing, utility stores and so on. Thus, Chip on Board (COB) is the latest improvement in LED innovation utilizing chips with different diodes (normally 9, or more). There is no packaging with COB innovation which empowers a much denser LED exhibit of light contrasted with SMD. A reliable and controlled light shaft is emitted, with no visible individual light focuses, in this way offering incredible optics. COB offers a significantly enhanced lumen for each watt proportion contrasted and other LED advances, for example, DIP and SMD. COB innovation gives the best conditions for ideal cooling, which thus build effectiveness and stretch the general existence of the light.