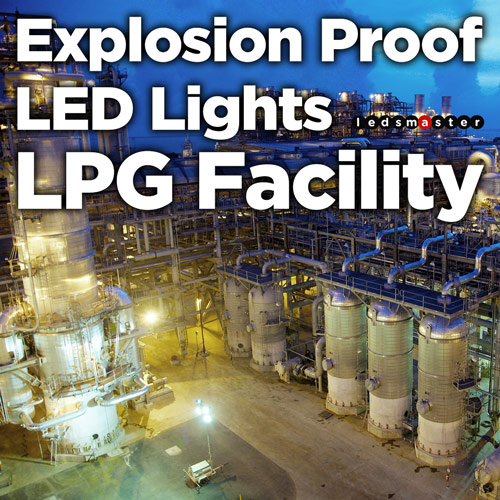

Explosion Proof Lighting for Liquefied Petroleum Gas Processing Facilities

Liquefied Petroleum Gas (LPG) is extremely useful and is an indispensable part of millions of homes across the country and also across the world. However, there is no doubt that LPG is extremely combustible and flammable. Therefore, when it comes to filling of LPG cylinders or transporting them across pipelines there are strict guidelines with regard to safety standards that need to be followed. These pertain to use of the best of early fire warning systems, pressure valve indicators and most importantly, monitoring of heat, humidity and other such things.

Liquefied Petroleum Gas (LPG) is extremely useful and is an indispensable part of millions of homes across the country and also across the world. However, there is no doubt that LPG is extremely combustible and flammable. Therefore, when it comes to filling of LPG cylinders or transporting them across pipelines there are strict guidelines with regard to safety standards that need to be followed. These pertain to use of the best of early fire warning systems, pressure valve indicators and most importantly, monitoring of heat, humidity and other such things.

We need to understand the importance of having LPG processing plant lighting systems that are safe and they should not add to the risk quotient in any manner whatsoever. Hence, there is a need to find out ways to ensure that the best possible explosion proof lighting arrangements are in place. We will try and the reasons as to why special lighting arrangements need to be made as far as LPG processing facilities are concerned.

1. The Environment & Atmosphere is Different

When we look at the environment in and around LPG processing facilities, there are some unique characteristics that should be always kept in mind. The atmosphere in and around a manufacturing facility could have concentrations of flammable dusts, fibers and vapors. This is all the truer for work spaces that are closed, confined and congested. There is every chance of vapor concentration building up and creating an increased risk of combustion and fire hazard.

Though flammable substances are carried and stored in the safest possible way and in tightly-sealed containers, the mere presence of these containers could make the entire location hazardous. These are just mere statement and if you go by the safety standards and standard operating procedures, the risk of fire caused by combustible atmospheric dust and debris is very real. Hence, there is a need to exercise great caution when planning, installing and operating of lighting systems are concerned. The norm of choosing the best possible explosion proof lighting is not unreal to say the least.

2. The Safety of Employees is of Paramount Importance

In view of the facts mentioned above, the safety and security of employees working in hazardous locations should always be the topmost priority of any organization. This in itself is good enough reason to install the right kind of LED lighting that has the right rating. The benefits of LED lighting in hazardous location have been well documented and it would be worth having a closer look at the same over the next few lines.

3. Why LED Lighting for Hazardous Locations

As is the case with other types and forms of LED lights, hazardous location lighting systems find a lot of benefits using LED devices. They are extremely energy efficient and also have long durability and life. Going by an average, LED lamps consume up to 85% lower electricity and they can work at optimal levels for around 80,000 hours. If properly used, they also can have a life-span of around 100,000 hours of operation. Specialized LED lighting systems for hazardous locations come with durable fixtures. These are made from special aluminum that is free of copper. They also have the best of technologies that play a positive role in reducing the temperature of the entire fixture. We need to bear in mind that lighting apparatuses often get heated up because of the fixtures. Apart from improving durability, the reduction of surface temperatures and internal temperature go a long way in reducing the risk of catastrophic ignition caused by the airborne debris and other flammable substances.

They Are Specially Designed

We also need to bear in mind that these Class 1 hazardous lighting fixtures are specially designed. They are suitable for environments where there could be presence of chemical vapors that could get ignited when certain vapors come in direct contact with the ignition source. The sources could include electric spark, and also lighting systems that get heated because of constant lighting and other chemical properties.

Conclusion

Hence, at the end of the day, there are many reasons to believe that LED lighting solutions could be the right answer for hazardous locations. They have been researched, tested under laboratory conditions and also have stood the test of time. They also offer good value for money while not compromising on safety factors under any circumstances.