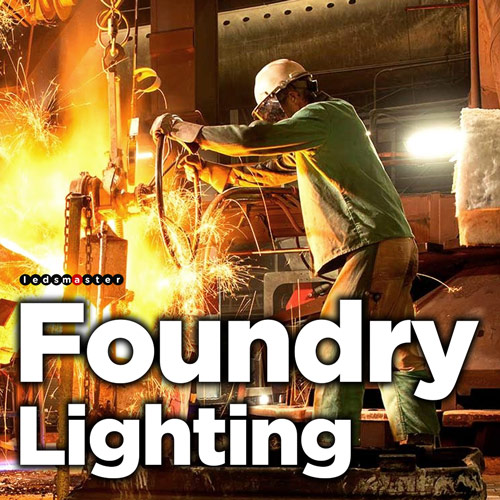

LED Foundry Lighting (Explosion Proof)

There is no doubt that foundries are becoming extremely important for driving the economy of all countries. To improve the safety and productivity of workers, we will need proper foundry lighting. LED is a better choice because it is explosion proof and energy efficient. Melting and furnace are the important processes as they not only help in manufacturing metal casting products that are used in a wide range of application, but they also help in providing employment to thousands of men and women across the country.

There is no doubt that foundries are becoming extremely important for driving the economy of all countries. To improve the safety and productivity of workers, we will need proper foundry lighting. LED is a better choice because it is explosion proof and energy efficient. Melting and furnace are the important processes as they not only help in manufacturing metal casting products that are used in a wide range of application, but they also help in providing employment to thousands of men and women across the country.

Most of the foundries are run as small or medium enterprises and therefore they might not be aware of the importance of good lighting inside the foundry. Products coming out from foundries are used in automotive, defense, aerospace, agriculture, mining, railroad, transportation, health-care and also in water infrastructure/municipal fields. While this is indeed great new, we need to take into account the risks of fire that emanate from foundries.

Therefore, a number of precautions have to be taken in foundries and this includes having the right explosion proof lighting. Though not many people may be aware of it, many fires and explosions in foundries are causes by wrong lighting arrangements. Hence, it would be interesting to know more about the need for the right lighting arrangements in foundries that could reduce the risk of fires and explosions.

How Should Lighting Be in Foundries

We all know that lighting should be bright and illuminative in foundries. However, at the same time we should also bear in mind that most conventional lighting systems generate quite a bit of heat. While this might be okay for homes and offices where good ventilation is available, it could be risky as far as foundries are concerned. When foundries are at work, they result in quite a bit of chemical changes in the atmosphere. This is all the more possible in foundries that are located in congested rooms with poor ventilation. When minerals and metals are melted, they result in the emission of chemical debris and dusts. These keep floating around in the environment unless there is a foolproof ventilation system in place. In such situations, having lighting systems that generated heat could be a recipe for disaster. When the heat generated by conventional lighting systems comes in contact with these chemical debris and dusts, there is a real danger of explosion and resultant fire. So, the best solutions have to be found and we will be sharing some tips that have stood the test of time.

Go in for LED Lighting Systems

Most foundries that have zero tolerance towards safety and security of its employees and the properties would most certainly go in for LED lighting systems. There are special LED lights and fittings that have reasonably higher thresholds when it comes to heating and other such risks. It is therefore, not very surprising to see that dozens of foundries are shifting to LED lighting to make their units explosion proof and fire hazard proof.

There Are Some Obvious Benefits

There is no doubt that there are other benefits and advantages of LED lighting systems apart from being explosion proof. The initial investment might be a bit high when compared to conventional lighting systems. But when it comes to durability and longevity, it has been proven time and again that LED lighting systems are much better. The icing on the cake is that it helps to cut down on energy costs by almost 70 to 85% in many cases. They are also environment friendly and do not contribute to greenhouse effect. This is a common problem with incandescent lamps, halogen lighting systems and mercury lighting systems. LED lighting also helps the fixtures, fittings and casings to remain cool and this is a great relief because a heated casing, fixtures and fittings could be a potential fire and explosion hazard because of the various factors mentioned above.