6 Tips to Choose the Best High Bay Lighting for Warehouse

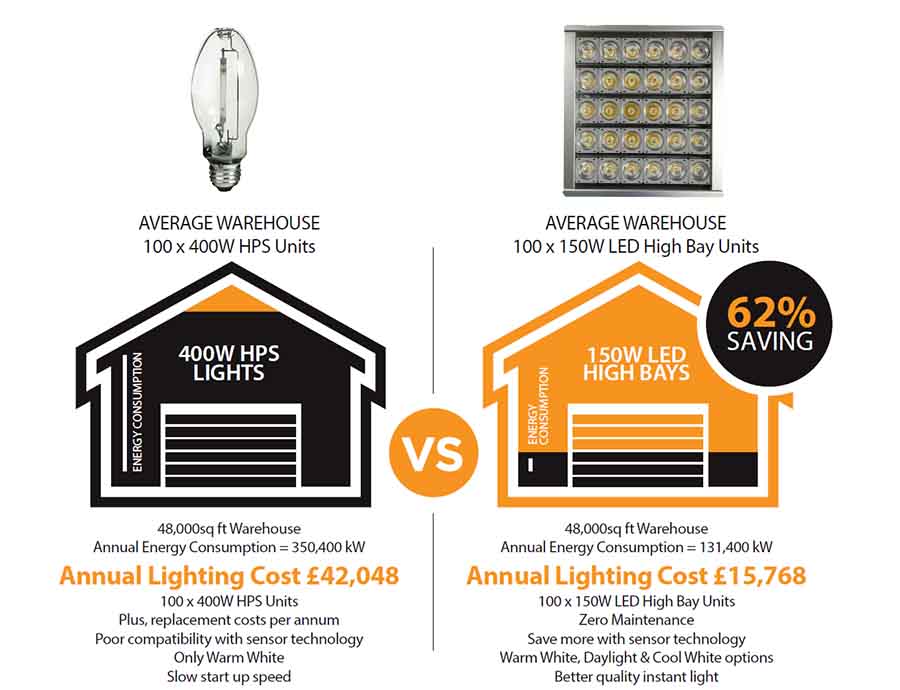

When it comes to warehouse lighting, productivity and safety should be the first and foremost concerns. Since storehouses generally have high ceiling, lighting up the whole space properly is challenging enough, apart from installation, we also need to reserve considerable amount of money to do the maintenance if poor luminaries are chosen. LED high bay lights are the best solutions to replace metal halide, halogen, HPS, LPS, fluorescent, because of LED’s high durability and lower electricity cost. Now you are probably wondering, how can I select the best lighting for warehouse? Here are 6 tips for you make the right decision.

1. Considering the dimension and design of warehouse

“I simply want to light up a warehouse with the size of xxx, please give me a solution”. Apart from the area, the height of the roof and the placement of your shelves affect the arrangement of lighting. For example, we need to use denser array of high bay linear flood lamps to light up a narrow aisle. Then, for the high ceiling, it would be better to use smaller beam angle to reserve the ground brightness. If you have a low roof and spacious area, we can use wider beam angle and less dense array to achieve better uniformity.

See also: High bay vs low bay lighting – their similarities and differences

2. Glare of the lighting

The dazzling light causes warehouse worker’s uncomfortableness. The are many dangerous machines and tools inside warehouse such as forklifts. The strong glare will irritate their eyes and affect them to see the people or goods next to them. According to the past news report, there are around 15% of accidents are related to improper lighting. And thus, having a good lighting system for warehouse is vital. Our LED products are equipped with exclusive lens that have built-in glare control function. This design can reduce the glare by 60% when comparing to the conventional lighting fixtures such metal halide and halogen flood lights.

3. Dimming function for warehouse

The first function of dimming is to maintain the consistency of brightness throughout the day. During daytime, since much sun light passes the windows, we can dim the warehouse lighting. In the evening, we can increase the brightness to provide adequate brightness for the workers. This flexible manipulation helps maintain the best working environment.

Light dimmer is very useful to save energy as well. Since there are many functions inside the storehouse and each of them have the best brightness requirement. For instance, we need higher lumens fore repair and less for general storage. It would be convenient for the use if the storehouse lighting can be dimmed for each purpose, without reinstall the light

Our warehouse aisle lighting supports PWM and DMX dimming system. You can also select the photo sensor & motion sensor to detect the brightness and if there are people respectively. If it is unnecessary to turn on the light or using the full brightness, the dimmer will decrease the brightness automatically.

4. Select high lighting efficiency high bay lights

Have you ever experienced that the light is not so bright even using 1000W? The possible reason is that you are using halogen or incandescent bulbs. Since they have very low energy efficiency, the brightness is very low even you use the “high power” luminary. Nonetheless, LED has 8 to 10 times higher luminous efficacy than these conventional lights. And hence 100W LED replaces 1000W halogen or metal halide lights. We have different powers available for the LED lighting products, from 60W to 10000W, and hence you can always find the most appropriate lighting solutions.

5. Choose high quality products

The installation cost is usually comparable to the lamp cost. And hence, selecting the high quality that works longer save your maintenance cost in long run. LED lights has 80000 hours life span, which is equal to 30 years use based on 6 to 7 hours use per day. If you are using metal halide, you may have experienced that you need to replace them almost every few months or every year. It is because the brightness declines very quickly for the non-LED lights.

You need to avoid the shoddy products in the market. Some manufacturers may have extreme low price, such as $40 for 100W LED. It is impossible unless they use poor quality LED chips and material.

6. Looking for customization service

Each venue has their unique setting, the ceiling height, area, brightness requirement for instance. Some warehouses have special purpose such as chemical manufacturing and cool storage. We may need explosion proof lighting or cool storage lighting. Reinforcement is needed to protect luminary so that they can work in emergency. You can always get the best lighting solutions at LedsMaster as we offer versatile, customized LED lights for industrial applications.

Our contact email: beatus@ledsmaster.com